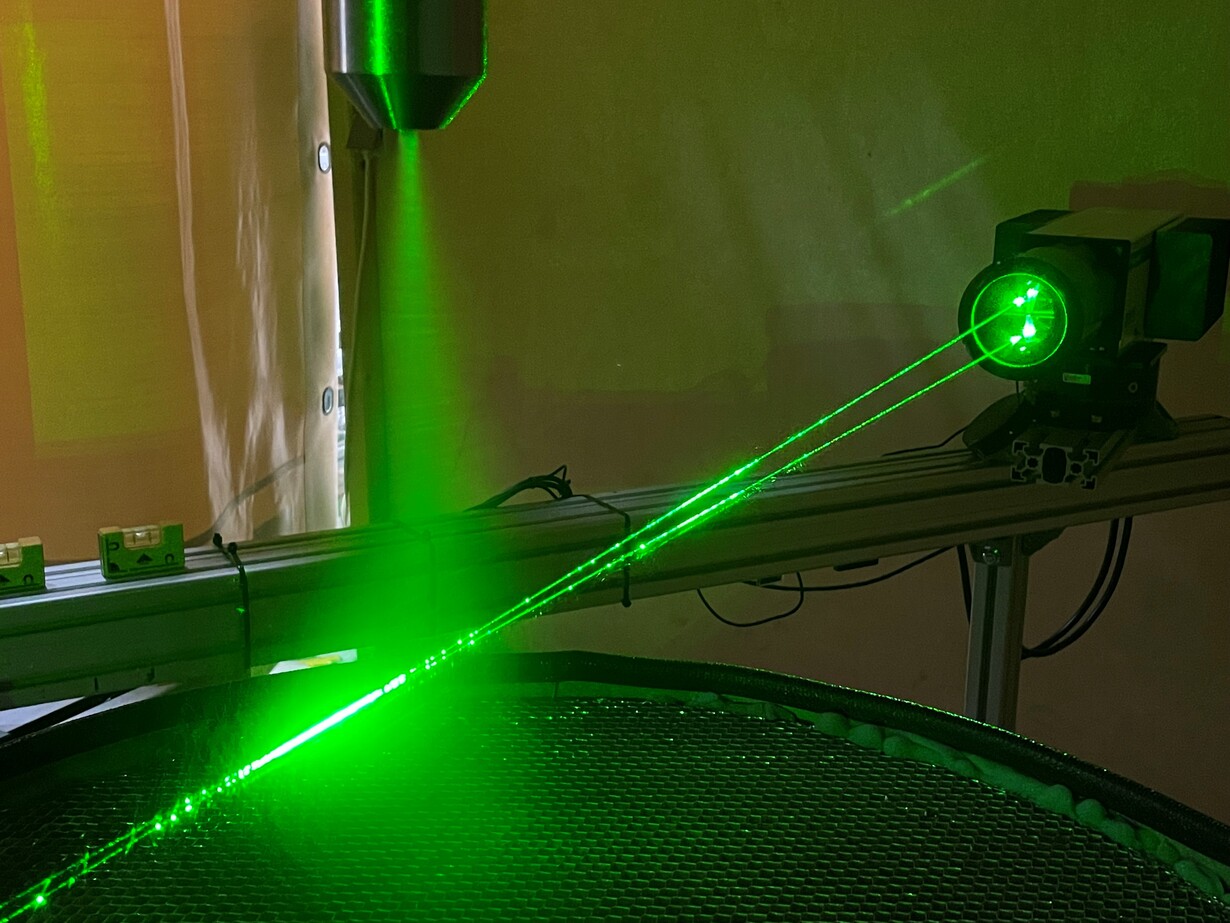

Video 1: The jet breakup of a highly viscous liquid applying a gas assisted coaxial external mixing nozzle

The aim of the research work is the optimization of gas-assisted nozzles with respect to the desired spray properties (e. g. spray angle and droplet size distribution), depending on the operating conditions and nozzle geometry.

To investigate the atomization process in the context of entrained flow gasification, three test facilities are operated (Pressurized Atomization Test Rig (PAT), ATMOspheric Spray Test Rig (ATMO) and the Burner Test Rig (BTR)). These allow for: (i) the investigation of the primary jet breakup (see video 1), (ii) the quantification of the prevailing instabilities and break-up mechanisms, (iii) the determination of the resulting droplet size and (iv) the characterization of the flow field. Various optical and laser-based measurement techniques (High-speed camera, Particle Image Velocimetry, Laser Doppler Anemometer, Phase Doppler Anemometer, Laser diffraction and a SpraySpy System) are available for the investigation of the whole spray cone. The raw data from the measurements are converted into data for quantifying the spray properties via an in-house code for post processing (SprayCat). As an example, this methodology allows us to determine a mass flow weighted integral Sauter mean diameter to characterize the droplet size in a defined cross-section of the spray at selected distances from the nozzle orifice.

Video 1: The jet breakup of a highly viscous liquid applying a gas assisted coaxial external mixing nozzle

Moreover, the experimental data serve to develop and validate predictive models for advanced numerical simulations of the atomization process. This work is conducted in close collaboration with the Chair for Simulation of reacting Thermo-Fluid Systems which is located at the Engler-Bunte-Institut at KIT and aims to establish a Virtual Spray Test Rig (VSTR). The VSTR will be based on relatively easily accessible data from the high-speed camera and shall be able to characterize and quantify the atomization process for different fluid viscosities, nozzle geometries and operating conditions. This research is embedded in the Helmholtz funded research program MTET – Materials and Technologies for the Energy Transition, in Topic 5 Ressource and Energy Efficiency.

Video 2 shows a direct comparison of exeprimental and simulation results [1,2]: Primary jet break-up of a highly viscous glycerol/water mixture (ηliq = 100 mPa s) at elevated pressure (p = 6 bar). A coaxial air-blast atomizer is used, where the liquid jet is atomized outside the nozzle orifice by a high velocity gas stream. The atomizer is operated at a Gas-to-Liquid-Ratio of GLR = 0.6 with a gas velocity of vgas = 60 m.s-1 . Left: High-speed camera video recorded at the Institute for Technical Chemistry. Right: Visualization of the liquid volume fraction integrated along a line of sight from VOF-LES predictions at Engler-Bunte-Institute.

Video 2: Experiment (left) and simulation (right) of the jet breakup of a gas assisted nozzle

(psys = 6 bar, ηliq =100 mPa.s, GLR = 0,6)