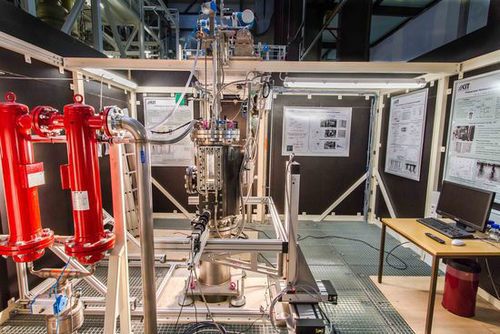

PAT - Pressurized Atomization Test Rig

Description:

The Pressurized Atomization Test Rig – PAT is used for the experimental investigation of spray quality at increased ambient pressure using high viscous fluids. The fluids are atomized in the pressurized spray chamber using twin fluid nozzles while spray quality is investigated using laser optical measuring techniques. Thus local drop size distribution is measured as function of the nozzle distance. Experimental investigation of spray quality can be performed varying chamber pressure (1 – 21 bar), fluid properties like viscosity and surface tension, operating conditions of the nozzle like GLR (Gas to Liquid Ratio), gas velocity, and nozzle geometry. Fluids can be pure liquids or suspensions featuring maximum viscosity of 1000 mPas.

To clarify the influence of ambient pressure on spray quality investigations of primary instabilities occurring during jet breakup are performed. Further experiments are focused on the influence of liquid viscosity on spray formation. The experimental data revealed at PAT allow for a better insight in the physical phenomena occurring during atomization, thus the data are used as a basis for evaluation and validation of CFD based modelling tools for optimization of burner nozzles for high pressure combustion chambers.

| Technical Data | ||

|---|---|---|

| Temperature | Tliq = 10 – 50 ° C |

Measuring technique:

|

| Pressure | 1 - 21 bar (abs) | |

| Massflow | liquid: 8 - 200 kg/h gas: 2 - 500 kg/h |

|

| Fluid-viscosity (liquid) |

1 - 1000 mPas |

|

Working group: Liquid Fuel / Atomization