Material Bulk Composition

Inorganic bulk analysis is carried out via, Elemental Analysis, Ion-Chromatography, Combustion-Ion Chromatography and X-ray Fluorescence Analysis.

Different standardized leaching test are used to investigate the availability of usable elements, like nutrients, and pollutants, i.e. heavy metals.

Analytic Quality Control

- Regular Control by analysis of certified reference materials

- Calibration in concentration range of the samples

- Control of calibration curves using standard solution from different suppliers

- At least double analysis of each sample

- Control analyses carried out in external labs where appropriate

- Regular control of tools , i.e. volumetric pipettes and (micro) balances ( with certified test weights)

Elemental Analysis C H N S

Elemental Analysis C H N S

Description:

- Sample combustion in oxygen

- Carrier gas: Helium

- Combustion temperature in CHN Micro oven: 950°C

- Combustion temperature in 628 S: 1350°C

- Analysis C H S via Infrared spectroscopy: CO2, H2O, SO2; analysis N2 via thermal conductivity detector

- Concentration range: 0,05 – 95 wt. %

Frequent samples:

biomass, pyrocoke and other pyrolysis products, plastics, cement, concrete, combustion residues: slags, ashes, slaggings and fouling samples from combustion chambers

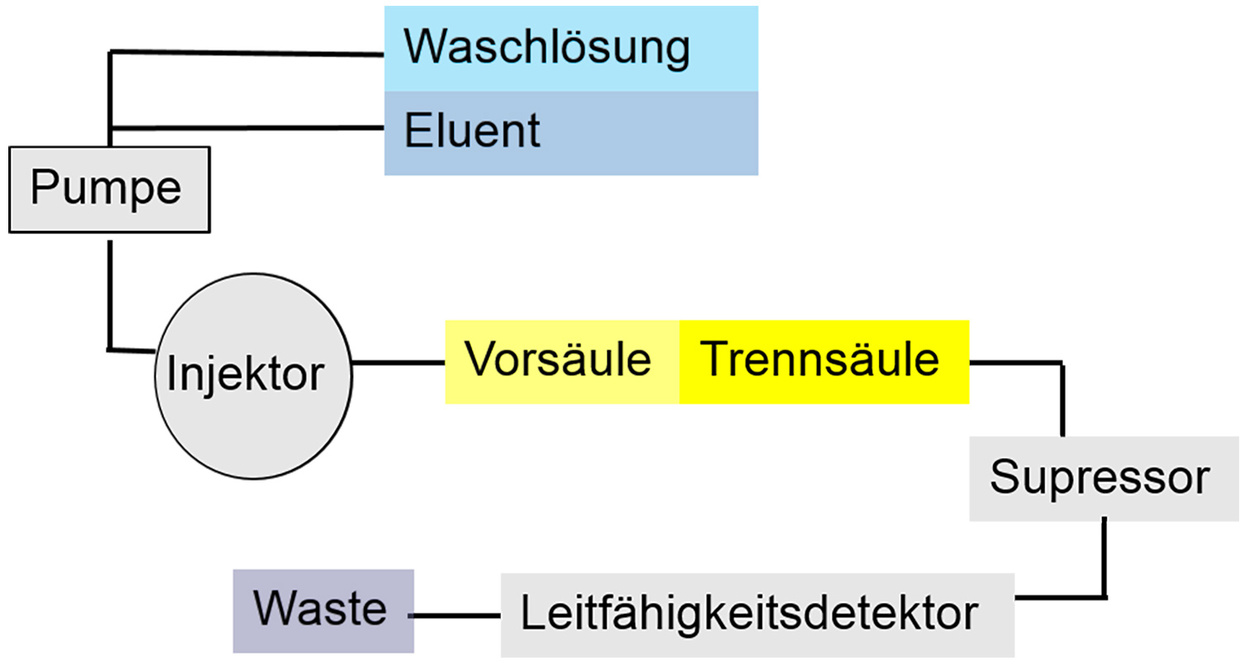

Ion chromatography for aqueous samples

Ion chromatography for aqueous samples

Description:

- Chromatographic anion separation

- Electrolytically generated eluent KOH (2mmol – 50 mmol)

- Self-generating supressor

- Conductivity detector

- Concentration range: 0,1mg/l – % (via dilution of samples)

Frequent samples:

- Leachates of combustion residues, pyro cokes according to standardized elution tests

- Aqueous condensates (pyrolysis, combustion, gasification)

Necessary condition: aqueous and clear solutions

doi.org/10.3390/membranes11020147

doi: 10.1007/s00216-011-5102-4

Combustion- Ionenchromatografie (C-IC)

Combustion- Ionenchromatografie (C-IC)

Beschreibung

- Hydropyrolyse im Argon-Wasserstrom mit anschließender Verbrennung im Sauerstoffstrom

- Aufschlusstemperatur 1100°C

- Verbrennungsgase in Absorptionsgefäß geleitet

- Direkte Injektion der Absorptionslösung in IC oder

Umleiten der Absorptionslösungen in Messkolben und Verdünnung möglich

- Konzentrationsbereich 15 mg/kg bis 50 wt.%

Feste, flüssige, pastöse Proben

Häufige Proben:

Zement, Aschen, Schlacken, Pyrolyseprodukte, Kunststoffe

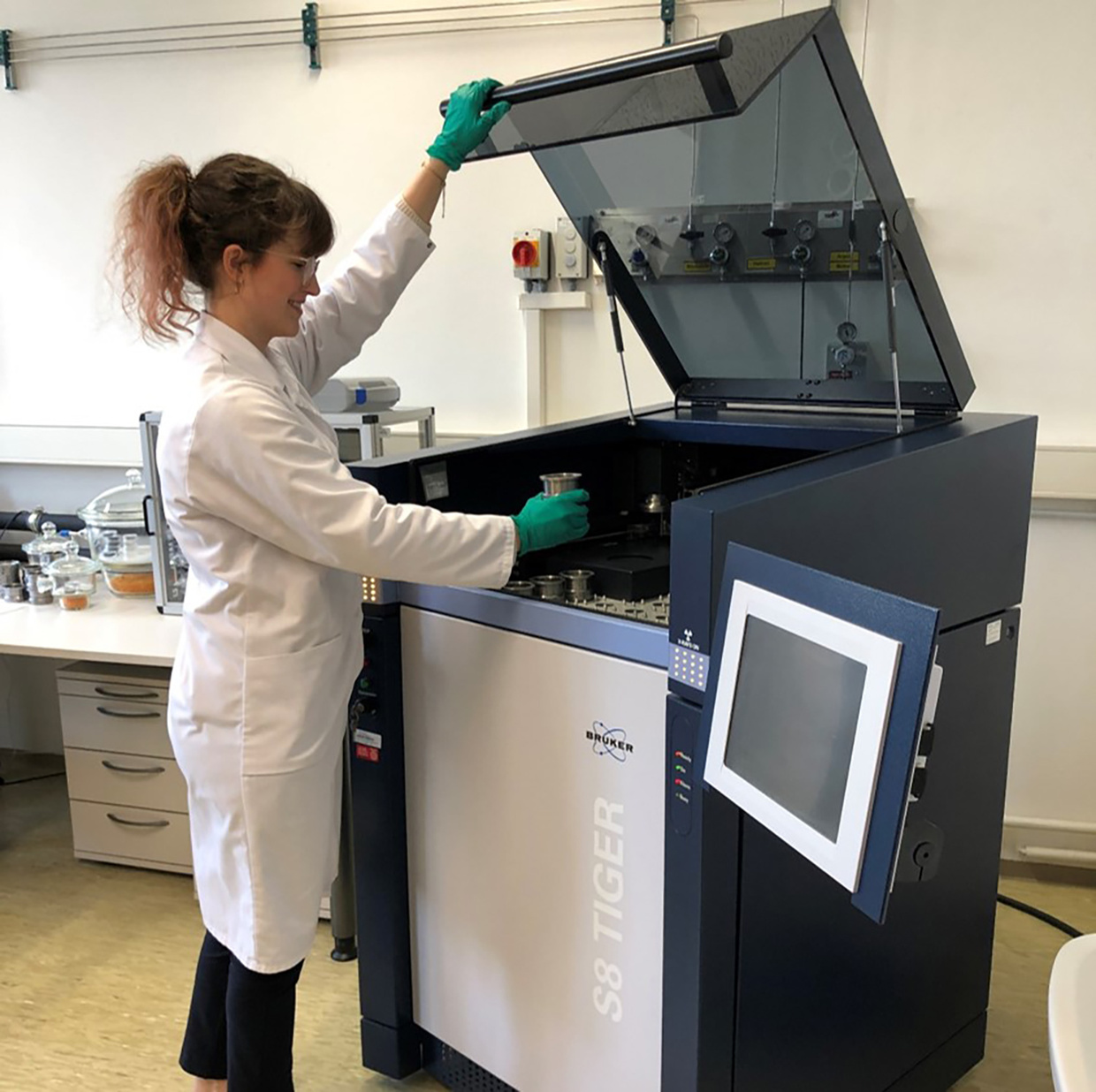

Wavelength dispersive X-Ray Fluorescence Spectrometry (WDXRF)

Wavelength dispersive X-Ray Fluorescence Spectrometry (WDXRF)

Description:

- Sequential wavelength dispersive X-ray fluorescence

- Rhodium x-ray tube

- Analyzer crystals: LiF(200), LiF (220), XS-Ge-C, PET, XS-55, XS-CEM

- Concentration range: 100 ppm - 100 wt.%

- Destruction free analysis for qualitative to semi quantitative analyses

- owder, solids and liquids

- Quantitative Analysis in Li-borate beads or wax tablet

- fine ground solids

Frequent samples:

Biomass ashes and coke, cement, concrete, combustion residues: slags, ashes, slaggings and fouling samples from combustion chambers among others

Int. J. Mol. Sci. 2021, 22, 9312. Link;

DOI: 10.5071/28thEUBCE2020-2BV.2.8; DOI: 10.5071/28thEUBCE2020-2BV.2.9;

DOI: 10.1016/j.wasman.2012.08.011

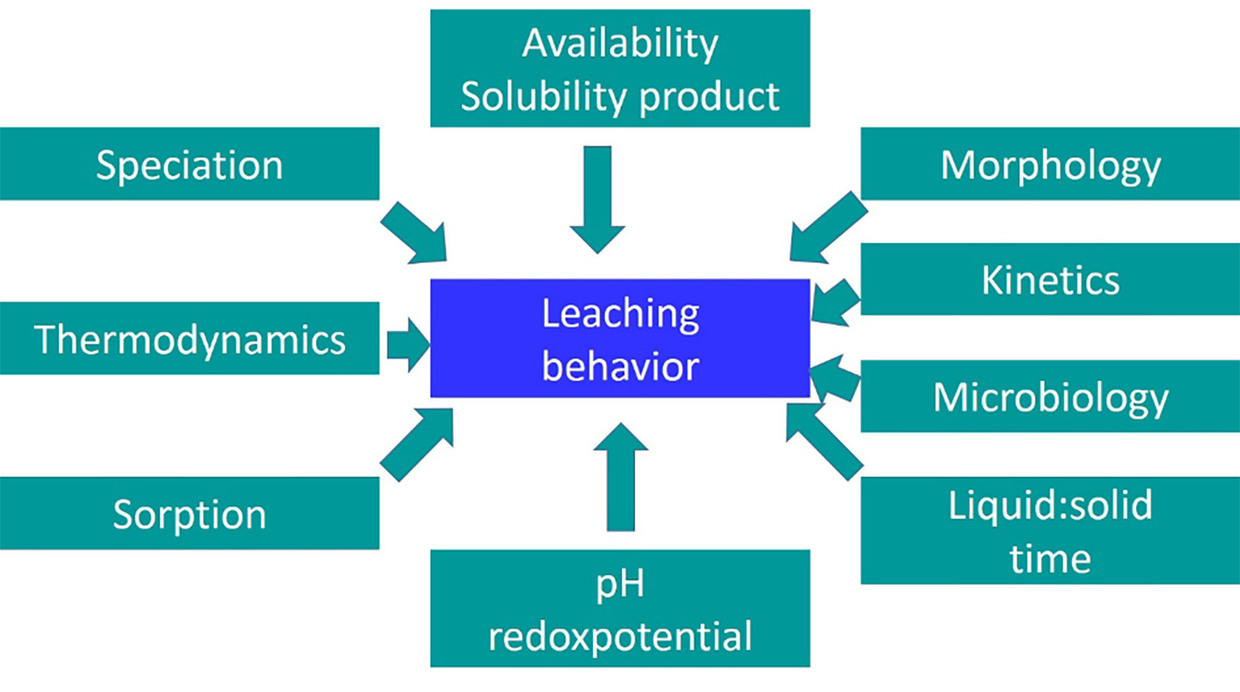

Leaching tests

Leaching tests

The concentration of an element in a solid gives no information about ist availability in a distinct environment. Hence, leaching tests are necessary to investigate the solubility of nutrients or pollutants in different settings.

The leaching behavior depends on a multitude of factors.

This allows for numerous different test parameters. Their variation can be used for various research approaches.

To compare leaching results with legal limits it is necessary to use standardized leaching tests.

Wir wenden u.a. folgende Verfahren an:

- DIN EN 12457-1 bis 4

- DIN EN 14405

- DIN EN 14997

- DIN EN 450-1

- DIN EN 15920

- DIN EN 15957

- DIN EN 15958

DOI: 10.3390/agriculture8120187; DOI: 10.1016/j.wasman.2012.12.005;

DOI: 10.1016/j.jhazmat.2011.02.045