Resource Efficient Processes

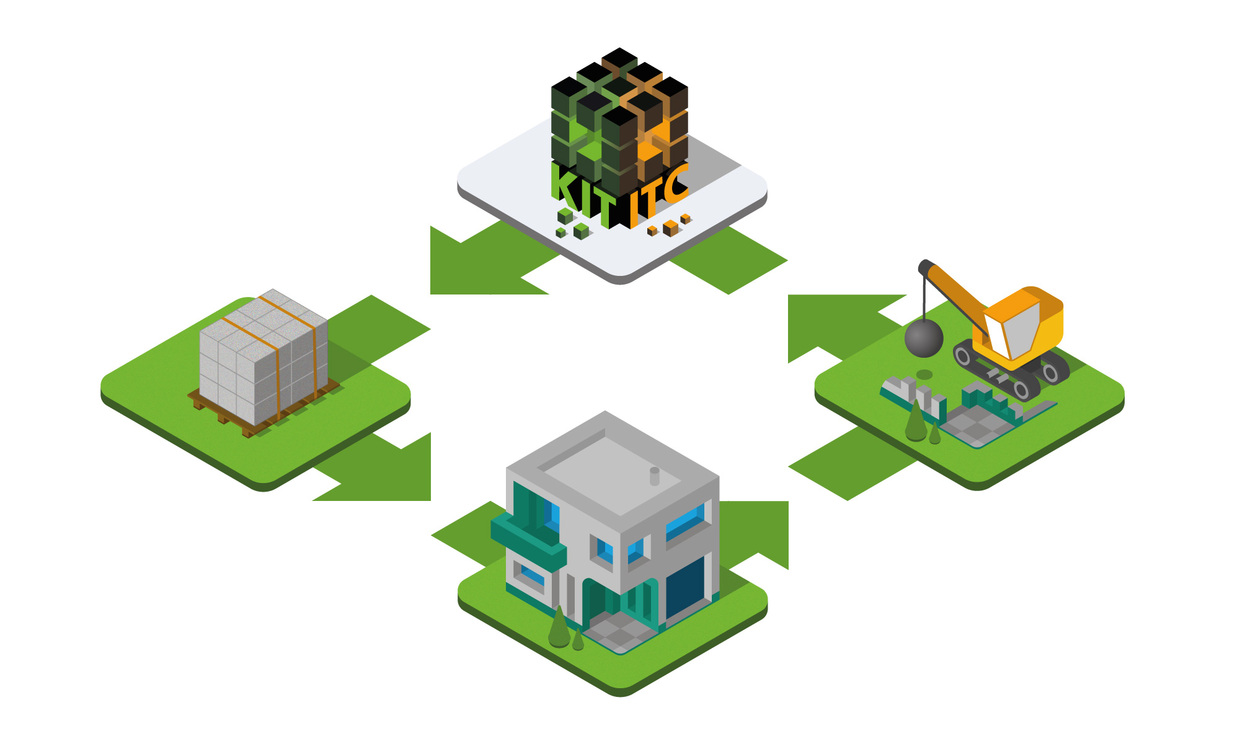

We design processes for a circular economy in the minerals industry to recycle primary and secondary raw materials. Such matter is predominantly used in construction, implying large quantities and the opportunity for quality recycling, at best as a new binder substituting cement.

Starting Points: Carbon dioxide and resources

a) synthesis processes are always connected to huge CO2 emissions because of the calcium involved and

b) recycling of e.g. concrete from demolition or mixed construction waste is in many cases actually downcycling as sub-construction of roads and disposal sites or mine backfilling - and not for re-introduction into production.

Goals: Construction waste to construction materials

...usage or even none at all. We design energy and material efficient processes and collaborate intensively with companies of waste processing, production, and application to use these materials for the replacement of primary resources for cement oder construction materials.