Gasification Technology

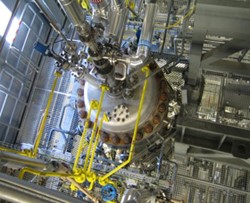

High pressure entrained flow gasification is one of the key technologies to close the anthropogenic carbon cycle.

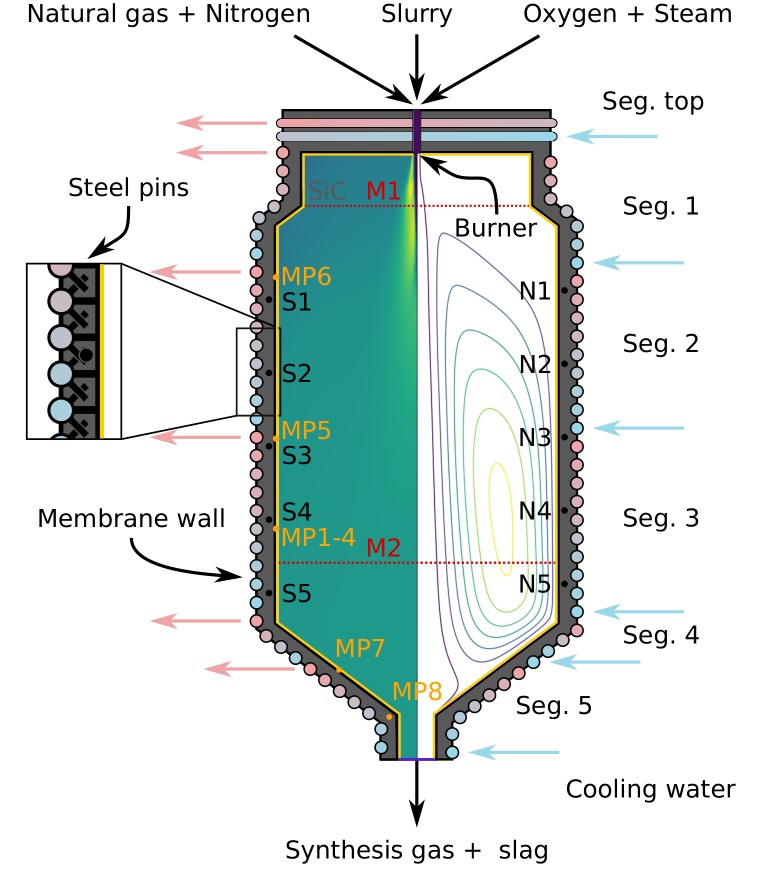

The research activities of the Department Gasification Technology focus on the conversion of biogenic and anthropogenic feedstock applying the thermo-chemical process of gasification. The sub processes atomization, flame stabilization, fuel conversion, slagging and heat release are investigated applying R&D facilities from lab to pilot-scale. The experimental data are the basis for physical models of the sub processes, which are implemented into numerical and flowsheet simulation tools. These simulation tools can be used for optimization of reactor design and of the process conditions and are the basis for scale-up and thus technology transfer to industrial application.

Research is carried out in close cooperation with the research group Thermochemical Fuel Conversion at Engler-Bunte-Institut, Fuel Technology, EBI ceb.

The work is funded by the Helmholtz program MTET (Materials and Technologies for the Energy Transition) in the subtopic Anthropogenic Carbon Cycle, Topic 5 (Resource and Energy Efficiency).

Networks

IEA – Task 33 Gasification of Biomass and Waste

Contact: Dr.-Ing. Sabine Fleck

ProcessNet (VDI / GVC / DECHEMA)

Section Sustainable Production, Energy and Resources (SuPER)

Subject divisions:

Contact: Prof. Dr.-Ing. Thomas Kolb

DGMK

German Society for Sustainable Energy Carriers, Mobility and Carbon Cycles e.V..

Contact: Prof. Dr.-Ing. Thomas Kolb

Projects

Helmholtz Programmorientierte Förderung: Materials and Technologies for the Energy Transition (MTET), Topic 5, Subtopic Anthropogenic Carbon Cycle

Cooperation

Publications

Haas, M.; Fleck, S.; Scheiff, F.; Kolb, T.

2026. Fuel, 416, 138473. doi:10.1016/j.fuel.2026.138473

Prabhakaran, P.

2026, February 12. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000190426

Santo, U.; Böning, D.; Jakobs, T.; Michelfelder, B.; Zimmerlin, B.; Kolb, T.; Scheiff, F.

2026. 8. Mitteleuropäische Biomassekonferenz (CEBC 2026), Graz, Austria, January 21–23, 2026

Kolb, T.; Mörs, F.; Graf, F.

2026. (W. Reschetilowski, Ed.), Springer-Verlag. doi:10.1007/978-3-662-69921-8

Dammann, M.; Hüsing, F.; Santo, U.; Böning, D.; Mancini, M.; Kolb, T.

2026. Fuel, 404, 134897. doi:10.1016/j.fuel.2025.134897

Walker, S.; Kolb, T.

2025. Energy & Fuels, 39 (49), 23291–23303. doi:10.1021/acs.energyfuels.5c04287

Scheiff, F.; Kolb, T.; Bajohr, S.; Graf, F.; Fleck, S.; Santo, U.; Jakobs, T.; Haas, M.; Heneka, M.; Köppel, W.

2025, October 29. DGMK "Hydrogen and Syngas" (2025), Essen, Germany, October 28–29, 2025

Dammann, M.; Mancini, M.; Kolb, T.; Weber, R.

2025, October 17. 20th International Conference on Numerical Combustion (ICNC 2025), Rome, Italy, October 14–17, 2025

Santo, U.; Böning, D.; Jakobs, T.; Fleck, S.; Michelfelder, B.; Zimmerlin, B.; Kolb, T.; Scheiff, F.

2025, September 18. 13th International Freiberg Conference on Circular Carbon Technologies (IFC 2025), Prague, Czechia, September 15–19, 2025

Richter, J.; Haas, M.; Jakobs, T.; Fleck, S.; Scheiff, F.; Kolb, T.

2025, September 17. 32. Deutscher Flammentag (2025), Paderborn, Germany, September 15–17, 2025

Haas, M.; Fleck, S.; Santo, U.; Jakobs, T.; Scheiff, F.; Kolb, T.

2025, September 17. 32. Deutscher Flammentag (2025), Paderborn, Germany, September 15–17, 2025

Schaefer, W.; Fleck, S.; Haas, M.; Jakobs, T.

2025. Photonics, (12), 673. doi:10.3390/photonics12070673

Santo, U.; Böning, D.; Fleck, S.; Jakobs, T.; Michelfelder, B.; Zimmerlin, B.; Scheiff, F.; Kolb, T.

2025, June 9. 33rd European Biomass Conference and Exhibition (EUBCE 2025), Valencia, Spain, June 9–12, 2025

Richter, J.; Roeb, J.; Zhang, F.; Stapf, D.; Stein, O. T.; Jakobs, T.; Kolb, T.

2025, May 12. 12th International Conference on Multiphase Flow (ICMF 2025), Toulouse, France, May 12–16, 2025

Haas, M.; Fleck, S.; Jakobs, T.; Kolb, T.

2025. Thermal Science and Engineering Progress, 59, Art.-Nr.: 103342. doi:10.1016/j.tsep.2025.103342

Haas, M.; Fleck, S.; Kolb, T.; Scheiff, F.

2025, March 20. 5th International Workshop on Oxy-Fuel Combustion (2025), Aachen, Germany, March 19–20, 2025

Fleck, S.; Haas, M.; Santo, U.; Tavakkol, S.; Stapf, D.; Kolb, T.; Scheiff, F.

2025, March 18. Jahrestreffen der DECHEMA-Fachgruppen Abfallbehandlung und Wertstoffrückgewinnung (AuW), Hochtemperaturtechnik (HTT) und Rohstoffe (ROH 2025), Dresden, Germany, March 17–18, 2025

Schäfer, W.; Haas, M.; Fleck, S.; Jakobs, T.

2025, February 3. Jahrestreffen der DECHEMA/VDI-Fachgruppe Fluidverfahrenstechnik (2025), Bochum, Germany, February 3–5, 2025

Walker, S.; Kolb, T.

2025. Fuel, 381 (Part C), 133561. doi:10.1016/j.fuel.2024.133561

Dammann, M.; Santo, U.; Böning, D.; Knoch, H.; Eberhard, M.; Kolb, T.

2025. Fuel, 382, 132809. doi:10.1016/j.fuel.2024.132809

Santo, U.; Böning, D.; Jakobs, T.; Fleck, S.; Michelfelder, B.; Zimmerlin, B.; Scheiff, F.; Kolb, T.

2025. The 13th International Freiberg Conference on Circular Carbon Technologies

Roeb, J.; Richter, J.; Jakobs, T.; Kolb, T.; Scheiff, F.; Stapf, D.; Stein, O. T.

2025. 21st Multiphase Flow Workshop - Conference and Short Course (2025), Dresden, Germany, November 10–14, 2025

Dammann, M.; Weber, R.; Fateev, A.; Clausen, S.; Alberti, M.; Kolb, T.; Mancini, M.

2024. Journal of Quantitative Spectroscopy and Radiative Transfer, 329, 109121. doi:10.1016/j.jqsrt.2024.109121

Dammann, M.; Walker, S. C.; Mancini, M.; Kolb, T.

2024. Fuel, 375, Art.-Nr.: 131967. doi:10.1016/j.fuel.2024.131967

Dammann, M.

2024, October 8. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000172116

Haas, M.; Fleck, S.; Kolb, T.

2024, September 10. International Conference on Thermochemical Conversion Science: Biomass & Municipal Solid Waste to RNG, Biofuels & Chemicals (tcbiomass2024 2024), Itasca, IL, USA, September 10–12, 2024

Kaltschmitt, M.; Fleck, S.; Kolb, T.

2024. (H. Hofbauer & V. Lenz, Eds.), Springer Fachmedien Wiesbaden. doi:10.1007/978-3-658-41216-6

Haas, M.; Fleck, S.; Jakobs, T.; Kolb, T.

2024, April 2. 14th European Conference on Industrial Furnaces and Boilers (INFUB 2024), Salgados, Portugal, April 2–5, 2024

Santo, U.; Böning, D.; Jakobs, T.; Fleck, S.; Michelfelder, B.; Zimmerlin, B.; Kolb, T.

2024, March 25. Jahrestreffen der DECHEMA-Fachgruppen Abfallbehandlung und Wertstoffrückgewinnung und Gasreinigung (FGr AuW und GAS 2024), Dresden, Germany, March 25–26, 2024

Jakobs, T.; Wachter, S.; Fleck, S.; Kolb, T.

2024, March 20. Jahrestreffen der DECHEMA/VDI-Fachgruppen Mehrphasenströmung, Computational Fluid Dynamics und Aerosoltechnik (2024), Bremen, Germany, March 20–21, 2024

Fleck, S.; Haas, M.; Santo, U.; Jakobs, T.; Kolb, T.

2024, March 19. Jahrestreffen der ProcessNet Fachgruppe Hochtemperaturtechnik (2024), Lindlar, Germany, March 19–20, 2024

Jakobs, T.; Richter, J.; Santo, U.; Haas, M.; Fleck, S.; Kolb, T.

2024, February 21. 3rd Materials and Technologies for the Energy Transition / Topic-Workshop "Resource and Energy Efficiency" (MTET 2024), Karlsruhe, Germany, February 21–22, 2024

E-Moghaddam, M.; Dahmen, N.; Santo, U.; Sauer, J.

2024. Energy & Fuels, 38 (5), 4229–4243. doi:10.1021/acs.energyfuels.3c04524

Dammann, M.; Mancini, M.; Kolb, T.; Weber, R.

2023. Thermal Science and Engineering Progress, 42, Art.-Nr.: 101772. doi:10.1016/j.tsep.2023.101772

Wachter, S.

2023, June 26. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000159585

Fleck, S.; Haas, M.; Santo, U.; Jakobs, T.; Kolb, T.

2023, June 12. Helmholtz Energy Conference (2023), Koblenz, Germany, June 12–13, 2023

Haas, M.; Fleck, S.; Kolb, T.

2023, March 29. Jahrestreffen der ProcessNet Fachgruppe Hochtemperaturtechnik (2023), Karlsruhe, Germany, March 28–29, 2023

Jakobs, T.; Richter, J.; Wachter, S.; Fleck, S.; Kolb, T.

2023, March 28. Jahrestreffen der ProcessNet Fachgruppe Hochtemperaturtechnik (2023), Karlsruhe, Germany, March 28–29, 2023

Hotz, C.; Haas, M.; Wachter, S.; Fleck, S.; Kolb, T.

2023. Fuel, 335, Article no: 126912. doi:10.1016/j.fuel.2022.126912

Haas, M.; Dammann, M.; Fleck, S.; Kolb, T.

2023. Fuel, 334 (2), Art.-Nr.: 126572. doi:10.1016/j.fuel.2022.126572

Prabhakaran, P.; Graf, F.; Koeppel, W.; Kolb, T.

2023. Energy Conversion and Management, 276, Art.Nr. 116534. doi:10.1016/j.enconman.2022.116534

Jakobs, J.; Haas, M.; Fleck, S.; Santo, U.; Kolb, T.

2023. 11th International Freiberg Conference (2023), Rotterdam, Netherlands, September 24–29, 2023

Zhang, F.; Wachter, S.; Zirwes, T.; Jakobs, T.; Zarzalis, N.; Trimis, D.; Kolb, T.; Stapf, D.

2023. Physics of Fluids, 35 (4), Art.-Nr.: 043302. doi:10.1063/5.0141156

Zhang, F.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.; Bockhorn, H.; Stapf, D.

2023. International journal of multiphase flow, 158, Art.-Nr.: 104304. doi:10.1016/j.ijmultiphaseflow.2022.104304

Matthes, J.; Kollmer, M.; Eberhard, M.; Hagenmeyer, V.; Kolb, T.

2022. Chemical Engineering & Technology, 45 (12), 2313–2322. doi:10.1002/ceat.202200434

Jakobs, T.; Wachter, S.; Haas, M.; Fleck, S.; Kolb, T.

2022, September 14. DECHEMA 2022 Jahrestagung - (Bio)Process Engineering - a Key to Sustainable Development (2022), Aachen, Germany, September 12–15, 2022

Haas, M.; Fleck, S.; Böning, D.; Santo, U.; Kolb, T.

2022. Chemie Ingenieur Technik, 94 (9), 1294–1294. doi:10.1002/cite.202255060

Jakobs, T.; Wachter, S.; Haas, M.; Fleck, S.; Kolb, T.

2022. Chemie - Ingenieur - Technik, 94 (9), Article no: 1215. doi:10.1002/cite.202255022

Zimmerlin, B.; Eberhard, M.; Dahmen, N.; Lam, H.; Mai, R.; Michelfelder, B.; Niebel, A.; Otto, T.; Pfitzer, C.; Willy, M.; Kolb, T.; Sauer, J.; Stapf, D.

2022, September. 2. Waste2H2-Workshop : Workshop and Summerschool (2022), KIT, September 19–26, 2022

Sauerschell, S.; Bajohr, S.; Kolb, T.

2022. Energy & Fuels, 36 (13), 7166–7176. doi:10.1021/acs.energyfuels.2c00655

Beerbaum, D.

2022, April 21. 13th European Conference on Industrial Furnaces and Boilers (INFUB 2022), Albufeira, Portugal, April 19–22, 2022

Dammann, M.; Mancini, M.; Kolb, T.; Weber, R.

2022, April. 13th European Conference on Industrial Furnaces and Boilers (INFUB 2022), Albufeira, Portugal, April 19–22, 2022

Dammann, M.; Mancini, M.; Kolb, T.; Weber, R.

2022. Conference proceedings der 13. European Conference on Industrial Furnaces and Boilers (INFUB-13), 19.04.2022-22.04.2022, Algarve, Portugal, Centro de Energia e Tecnologia (CENERTEC)

Beerbaum, D.; Bernhardt, D.; Jakobs, T.; Beckmann, M.; Kolb, T.

2022. 13th European Conference on Industrial Furnances and Boilers (INFUB 2022), Algarve, P, April 19-22, 2022

Mrosk, C.; Kolb, T.; Stapf, D.; Sauer, J.

2022. LookIT. LookKIT : Das Magazin für Forschung, Lehre, Innovation, (01/2022), 38–41

Wachter, S.; Jakobs, T.; Kolb, T.

2022. Applied Sciences (Switzerland), 12 (4), Art.-Nr.: 2123. doi:10.3390/app12042123

Hotz, C.; Haas, M.; Wachter, S.; Fleck, S.; Kolb, T.

2021. Fuel, 304, Art.-Nr.: 121392. doi:10.1016/j.fuel.2021.121392

Schneider, C.

2021, October 21. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000139237

Beerbaum, D.; Bernhardt, D.; Beckmann, M.; Jakobs, T.; Kolb, T.

2021, September 29. 30. Deutscher Flammentag (2021), Hanover, Germany, September 28–29, 2021

Haas, M.; Fleck, S.; Kolb, T.

2021, September 28. 30. Deutscher Flammentag (2021), Hanover, Germany, September 28–29, 2021

Santo, U.; Böning, D.; Eberhard, M.; Schmid, H.; Kolb, T.

2021, September 28. 30. Deutscher Flammentag (2021), Hanover, Germany, September 28–29, 2021

Zhang, F.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.; Bockhorn, H.

2021. 30. Deutscher Flammentag, Deutsche Sektion des Combustion Institutes und DVV/VDI-Gesellschaft Energie und Umwelt. Ed.: F. Dinkelacker, 1116–1125

Beerbaum, D.; Bernhardt, D.; Beckmann, M.; Jakobs, T.; Kolb, T.

2021. 30. Deutschen Flammentag, Hannover, 28.9.-29.09.2021. Hrsg.: Deutsche Vereinigung für Verbrennungsforschung e.V

Haas, M.; Kolb, T.

2021, September 13. 4th Doctoral Colloquium BIOENERGY (DOC2021 2021), Karlsruhe, September 13–14, 2021

Dammann, M.; Mancini, M.; Weber, R.; Kolb, T.

2021. Conference proceedings des 30. Deutschen Flammentag (2021), 28.09.2021 – 29.09.2021, Hannover, Deutschland, Deutsche Vereinigung für Verbrennungsforschung e.V

Dammann, M.; Mancini, M.; Weber, R.; Kolb, T.

2021, September. 30. Deutscher Flammentag (2021), Hanover, Germany, September 28–29, 2021

Schneider, C.; Zeller, M.; Böhm, D.; Kolb, T.

2021. Fuel, 299, Art.-Nr. 120523. doi:10.1016/j.fuel.2021.120523

Wachter, S.; Jakobs, T.; Kolb, T.

2021. Industrial & engineering chemistry research, 60 (30), 11502–11512. doi:10.1021/acs.iecr.1c01526

Wachter, S.; Jakobs, T.; Kolb, T.

2021. Applications in energy and combustion science, 5, Art.-Nr. 100019. doi:10.1016/j.jaecs.2020.100019

Eberhard, M.; Santo, U.; Schmid, H.; Zimmerlin, B.; Weigand, P.; Kolb, T.

2021. 7th International Symposium on Gasification and its Applications (ISGA 2021), Online, September 27–30, 2021

Santo, U.; Böning, D.; Eberhard, M.; Schmid, H.; Kolb, T.

2021. 30. Deutschen Flammentag, Hannover, 28.9.-29.09.2021, Deutsche Vereinigung für Verbrennungsforschung e.V

Wachter, S.; Jakobs, T.; Kolb, T.

2021. ICLASS 2021, 15thTriennial International Conference on Liquid Atomization and Spray Systems, Edinburgh, UK, 29 Aug. -2 Sept. 2021. Vol: 1,1, Paper 31. doi:10.2218/iclass.2021.5808

Mielke, K.; Wu, G.; Eberhard, M.; Kolb, T.; Müller, M.

2021. Chemical engineering & technology, 44 (7), Art. ceat.202000531. doi:10.1002/ceat.202000531

Schneider, C.; Walker, S.; Phounglamcheik, A.; Umeki, K.; Kolb, T.

2021. Fuel, 283, Article no: 118826. doi:10.1016/j.fuel.2020.118826

Zhang, F.; Zirwes, T.; Müller, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.

2020. Renewable & sustainable energy reviews, 134, Article no: 110411. doi:10.1016/j.rser.2020.110411

Graf, F.; Sauerschell, S.; Prabhakaran, P.; Bajohr, S.; Slama, J.; Stapf, D.; Kolb, T.

2020. Energie-, Wasser-Praxis, (10), 43–49

Mielke, K.; Kolb, T.; Müller, M.

2020. Biomass and bioenergy, 141, Art.-Nr. 105732. doi:10.1016/j.biombioe.2020.105732

Bähr, J.; Raffelt, K.

2020, September 28. (M. Eberhard, Ed.), Abschlusskonferenz Energie System 2050 (2020), Berlin, Germany, September 28–29, 2020

Graf, F.; Sauerschell, S.; Prabhakaran, P.; Bajohr, S.; Slama, J.; Stapf, D.; Kolb, T.

2020. Energie-, Wasser-Praxis, (9), 26–29

Eberhard, M.; Santo, U.; Michelfelder, B.; Günther, A.; Weigand, P.; Matthes, J.; Waibel, P.; Hagenmeyer, V.; Kolb, T.

2020. ChemBioEng reviews, 7 (4), 1–14. doi:10.1002/cben.202000006

Rincón Prat, S.; Schneider, C.; Kolb, T.

2020. Fuel, 267, Article No.117179. doi:10.1016/j.fuel.2020.117179

Wachter, S.; Jakobs, T.; Kolb, T.

2020. International journal of multiphase flow, 125, Article no: 103189. doi:10.1016/j.ijmultiphaseflow.2019.103189

Stoesser, P.

2020, March 12. Verlag Dr. Hut

Chaussonnet, G.; Joshi, S.; Wachter, S.; Koch, R.; Jakobs, T.; Kolb, T.; Bauer, H.-J.

2020. Journal of engineering for gas turbines and power, 142 (3), Art.Nr. 031019. doi:10.1115/1.4044968

Wachter, S.; Jakobs, T.; Kolb, T.

2020. Applied Sciences, 10 (21), Article no: 7615. doi:10.3390/app10217615

Schneider, S.; Bajohr, S.; Graf, F.; Kolb, T.

2020. ChemBioEng reviews, 7 (5), 150–158. doi:10.1002/cben.202000014

Held, M.; Schollenberger, D.; Sauerschell, S.; Bajohr, S.; Kolb, T.

2020. Chemie - Ingenieur - Technik, 92 (5), 595–602. doi:10.1002/cite.201900181

Prabhakaran, P.; Giannopoulos, D.; Köppel, W.; Mukherjee, U.; Remesh, G.; Graf, F.; Trimis, D.; Kolb, T.; Founti, M.

2019. Journal of energy storage, 26, 100987. doi:10.1016/j.est.2019.100987

Kolb, T.; Eberhard, M.; Santo, U.; Zimmerlin, B.

2019, November 4. Jahrestreffen der ProcessNet-Fachgemeinschaften "Prozess-, Apparate- und Anlagentechnik" unterstützt durch „Sustainable Production, Energy and Resources" (2019), Dortmund, Germany, November 4–5, 2019

Dammann, M.; Mancini, M.; Fleck, S.; Weber, R.; Kolb, T.

2019, September. 29. Deutscher Flammentag (2019), Bochum, Germany, September 17–18, 2019

Dammann, M.; Mancini, M.; Fleck, S.; Weber, R.; Kolb, T.

2019. Conference proceedings des 29. Deutschen Flammentag (2019), 17.09.2019 – 18.09.2019, Bochum, Deutschland

Wachter, S.; Jakobs, T.; Kolb, T.

2019, April 3. Jahrestreffen der ProcessNet-Fachgruppe "Hochtemperaturtechnik" (2019), Karlsruhe, Germany, April 2–3, 2019

Chaussonnet, G.; Braun, S.; Dauch, T.; Keller, M.; Sänger, A.; Jakobs, T.; Koch, R.; Kolb, T.; Bauer, H.-J.

2019. Computers & fluids, 180, 68–81. doi:10.1016/j.compfluid.2019.01.010

Fleck, S.; Santo, U.; Eberhard, M.; Haas, M.; Kolb, T.

2019. 29. Deutscher Flammentag Bochum, 17-18 September 2019

Fleck, S.; Santo, U.; Eberhard, M.; Haas, M.; Kolb, T.

2019. 29. Deutscher Flammentag (2019), Bochum, Germany, September 17–18, 2019

Haas, M.; Fleck, S.; Hotz, C.; Kolb, T.

2019. Jahrestreffen der ProcessNet-Fachgruppe "Hochtemperaturtechnik" (2019), Karlsruhe, Germany, April 2–3, 2019

Schneider, C.; Rincón Prat, S.; Kolb, T.

2019. Fuel, 267, Article No.116726. doi:10.1016/j.fuel.2019.116726

Müller, C.; Anghilante, R.; Schmid, M.; Härdtlein, M.; Spörl, R.; Colomar, D.; Ortloff, F.; Eltrop, L.; Graf, F.; Bajohr, S.; Kolb, T.

2019. Chemie - Ingenieur - Technik, 92 (1-2), 144–155. doi:10.1002/cite.201900097

Zhang, F.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Dimosthenis, T.; Kolb, T.

2019. 29th European Conference on Liquid Atomization and Spray Systems, Paris, 2-4 Sep 2019

Wachter, S.; Jakobs, T.; Kolb, T.

2019. 29th European Conference on Liquid Atomization and Spray Systems, Paris, 2-4 Sep 2019

Chaussonnet, G.; Dauch, T.; Braun, S.; Keller, M.; Kaden, J.; Schwitzke, C.; Jakobs, T.; Koch, R.; Bauer, H.-J.

2019. High Performance Computing in Science and Engineering ’ 18 – Transactions of the High Performance Computing Center, Stuttgart (HLRS) 2018. Ed.: W. Nagel, 309–322, Springer International Publishing. doi:10.1007/978-3-030-13325-2_19

Zhang, F.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.

2019. 29th European Conference Liquid Atomization & Spray Systems (ILASS 2019), Paris, France, September 2–4, 2019

Zhang, F.; Müller, T.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.

2019. 29. Deutscher Flammentag (2019), Bochum, Germany, September 17–18, 2019

Chaussonnet, G.; Joshi, S.; Wachter, S.; Koch, R.; Jakobs, T.; Kolb, T.; Bauer, H.-J.

2019. Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition (GT2019), The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2019-90372

Zimmerlin, B.; Eberhard, M.; Lam, H.; Mai, R.; Michelfelder, B.; Niebel, A.; Otto, T.; Pfitzer, C.; Weih, N.; Willy, M.; Leibold, H.; Dahmen, N.; Kolb, T.; Sauer, J.; Stapf, D.

2019. DGMK-Fachbereichstagung: Thermochemische Konversion – Schlüsselbaustein für zukünftige Energie- und Rohstoffsysteme (2019), Dresden, Germany, May 23–24, 2019

Zimmerlin, B.; Eberhard, M.; Lam, H.; Mai, R.; Michelfelder, B.; Niebel, A.; Otto, T.; Pfitzer, C.; Weih, N.; Willy, M.; Leibold, H.; Dahmen, N.; Kolb, T.; Sauer, J.; Stapf, D.

2019. DGMK-Fachbereichstagung: Thermochemische Konversion – Schlüsselbaustein für zukünftige Energie- und Rohstoffsysteme, Dresden, 23.-24. Mai 2019

Mörs, F.; Graf, F.; Kolb, T.

2019. Handbuch Chemische Reaktoren: Grundlagen und Anwendungen der Chemischen Reaktionstechnik. Hrsg.: W. Reschetilowski, 1–32, Springer Spektrum. doi:10.1007/978-3-662-56444-8_33-1

Zimmerlin, B.; Dahmen, N.; Kolb, T.; Neuberger, M.; Sauer, J.; Stapf, D.

2019. Jahrestreffen der ProcessNet-Fachgruppe "Hochtemperaturtechnik" (2019), Karlsruhe, Germany, April 2–3, 2019

Mancini, M.; Alberti, M.; Dammann, M.; Santo, U.; Eckel, G.; Kolb, T.; Weber, R.

2018. Fuel, 225, 596–611. doi:10.1016/j.fuel.2018.03.100

Nestler, F.; Berger, S.; Mayorga Gonzalez, R.; Full, J.; Hadrich, M. J.; White, R. J.; Schaadt, A.; Bajohr, S.; Kolb, T.

2018, June 4. International Workshop I "Perspectives on Power-to-Liquids & -Chemicals" (2018), Freiburg, Germany, June 4–5, 2018

Eberhard, M.; Santo, U.; Schmid, H.; Michelfelder, B.; Günther, A.; Weigand, P.; Stapf, D.; Kolb, T.; Zimmerlin, B.

2018, June 3. 9th International Freiberg Conference on IGCC & XtL Technologies (2018), Berlin, Germany, June 3–8, 2018

Covella, K.; Cavagnol, S. M.; Müller-Hagedorn, M.; Zimmerlin, B.; Kolb, T.

2018, June 3. 9th International Freiberg Conference on IGCC & XtL Technologies (2018), Berlin, Germany, June 3–8, 2018

Dammann, M.; Mancini, M.; Fleck, S.; Weber, R.; Kolb, T.

2018, May. Joint Meeting of the German and Italian Sections of the Combustion Institute (2018), Sorrento, Italy, May 23–26, 2018

Dammann, M.; Mancini, M.; Fleck, S.; Weber, R.; Kolb, T.

2018. Conference proceedings of the Joint Meeting of The German and Italian Sections of The Combustion Institute - 41st Meeting of the Italian Section of the Combustion Institute

Fleck, S.; Santo, U.; Hotz, C.; Jakobs, T.; Eckel, G.; Mancini, M.; Weber, R.; Kolb, T.

2018. Fuel, 217, 306–319. doi:10.1016/j.fuel.2017.12.077

Schneider, C.; Stoesser, P.; Rincon, S.; Kolb, T.

2018, February 15. 2nd International Workshop on Oxy-Fuel Combustion, Bochum, 14. - 15.02.2018

Eberhard, M.; Kolb, T.; u.a.

2018. (G. Aranda Almansa, C. Mourao Vilela & B. J. Vreugdenhil, Eds.), International Energy Agency (IAE)

Eberhard, M.; Kolb, T.; u.a.

2018. (G. Aranda Almansa, C. Mourao Vilela & B. J. Vreugdenhil, Eds.), International Energy Agency (IAE)

Eberhard, M.; Kolb, T.

2018. International Energy Agency (IAE)

Gegenheimer, J.; Schrelter, N.; Worch, D.; Trouillet, V.; Kureti, S.; Lubenau, U.; Ortloff, F.; Kolb, T.

2018. GWF / Gas, Erdgas, (10), 116–123

Zimmerlin, B.; Eberhard, M.; Dahmen, N.; Kolb, T.; Lam, H.; Mai, R.; Michelfelder, B.; Niebel, A.; Pfitzer, C.; Sauer, J.; Stapf, D.; Weigand, P.; Willy, M.

2018. Advanced Bioeconomy Leadership Conference (ABLC Global 2018), San Francisco, CA, USA, November 6–9, 2018

Sänger, A. D.

2018. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000087397

Sänger, A.; Jakobs, T.; Kolb, T.; Müller, T.; Kadel, K.; Habisreuther, P.; Trimis, D.; Zarzalis, N.

2018. ASME Turbo Expo : Turbomachinery Technical Conference and Exposition (GT), Oslo, Norway, June 11–15, 2018. Vol.: 3, Article no: 75950, The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2018-75950

Müller, T.; Kadel, K.; Habisreuther, P.; Trimis, D.; Zarzalis, N.; Sänger, A.; Jakobs, T.; Kolb, T.

2018. ASME Turbo Expo : Turbomachinery Technical Conference and Exposition GT2018, Oslo, Norway, June 11–15, 2018. Vol.: 3, Article no: 75945, The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2018-75945

Chaussonnet, G.; Braun, S.; Dauch, T.; Keller, M.; Kaden, J.; Jakobs, T.; Schwitzke, C.; Koch, R.; Bauer, H.-J.

2018. Proceedings of the 14th International Conference on Liquid Atomization & Spray Systems (ICLASS2018), Chicago, IL, July 22-26, 2018

Eckel, G.; Le Clercq, P.; Kathrotia, T.; Saenger, A.; Fleck, S.; Mancini, M.; Kolb, T.; Aigner, M.

2018. Fuel, 223, 164–178. doi:10.1016/j.fuel.2018.02.176

Eberhard, M.; Santo, U.; Böning, D.; Schmid, H.; Michelfelder, B.; Zimmerlin, B.; Günther, A.; Weigand, P.; Müller-Hagedorn, M.; Stapf, D.; Kolb, T.

2018. Chemie - Ingenieur - Technik, 90 (1-2), 85–98. doi:10.1002/cite.201700086

Chaussonnet, G.; Koch, R.; Bauer, H.-J.; Sänger, A.; Jakobs, T.; Kolb, T.

2018. Journal of fluids engineering, 140 (6), Art. Nr.: 061301. doi:10.1115/1.4038753

Stoesser, P.; Schneider, C.; Kreitzberg, T.; Kneer, R.; Kolb, T.

2018. Applied energy, 211, 582–589. doi:10.1016/j.apenergy.2017.11.037

Schneider, C.; Stoesser, P.; Rincon, S.; Kolb, T.

2017. Verbrennung und Feuerung : 28. Deutscher Flammentag 2017, Darmstadt, Germany, 6th - 7th September 2017, 331–343, VDI Verlag

Jampolski, L.; Jakobs, T.; Kolb, T.; Willenbacher, N.

2017. Chemical engineering & technology, 40 (10), 1885–1894. doi:10.1002/ceat.201700061

Schneider, C.; Stoesser, P.; Rincon, S.; Kolb, T.

2017. 28. Deutscher Flammentag (2017), Darmstadt, Germany, September 6–7, 2017

Stapf, D.; Dahmen, N.; Kolb, T.; Sauer, J.

2017. China-Workshop „Energie“, Karlsruhe, Germany, 25th - 26th July 2017

Chaussonnet, G.; Koch, R.; Bauer, H.-J.; Sänger, A.; Jakobs, T.; Kolb, T.

2017. Proceedings of ASME Turbo Expo 2017 : Turbomachinery Technical Conference & Exposition, Volume 3 : Coal, Biomass and Alternative Fuels, Cycle Innovations; Electric Power, Industrial and Cogeneration Applications, Organic Rankine Cycle Power Systems, Charlotte, North Carolina, USA, 26th - 30th June 2017, Art.Nr. GT2017–63033, The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2017-63033

Jampolski, L.; Tomasi Morgano, M.; Seifert, H.; Kolb, T.; Willenbacher, N.

2017. Energy & fuels, 31 (5), 5165–5173. doi:10.1021/acs.energyfuels.7b00196

Nau, P.; Kutne, P.; Eckel, G.; Meier, W.; Hotz, C.; Fleck, S.

2017. Applied optics, 56 (11), 2982–2990. doi:10.1364/AO.56.002982

Müller, T.; Dullenkopf, A.; Sänger, A.; Habisreuther, P.; Jakobs, T.; Zarzalis, N.; Kolb, T.

2017. Proceedings of the ASME Turbo Expo 2017: Turbine Technical Conference and Expo, ASME, Charlotte, NC, June 26-30, 2017

Müller, T.; Dullenkopf, A.; Habisreuther, P.; Zarzalis, N.; Sänger, A.; Jakobs, T.; Kolb, T.

2017. Proceedings of the ASME Turbo Expo 2017 : Turbomachinery Technical Conference and Exposition, Volume 3 : Coal, Biomass and Alternative Fuels : Cycle Innovations : Electric Power : Industrial and Cogeneration Applications : Organic Rankine Cycle Power Systems, Charlotte, North Carolina, USA, 26th - 30th June 2017, Art. Nr. V003T03A002, The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2017-63198

Seebold, S.; Eberhard, M.; Wu, G.; Yazhenskikh, E.; Sergeev, D.; Kolb, T.; Müller, M.

2017. Fuel, 197, 596–604. doi:10.1016/j.fuel.2017.02.027

Wu, J.; Yan, J.; Desideri, U.; Deconinck, G.; Madsen, H.; Huitema, G.; Kolb, T.

2017. Applied energy, 192, 263–267. doi:10.1016/j.apenergy.2017.02.038

Dahmen, N.; Abeln, J.; Eberhard, M.; Kolb, T.; Leibold, H.; Sauer, J.; Stapf, D.; Zimmerlin, B.

2017. Wiley interdisciplinary reviews / Energy and Environment, 6 (3), Article no e236. doi:10.1002/wene.236

Götz, M.; Lefebvre, J.; Mörs, F.; Ortloff, F.; Reimert, R.; Bajohr, S.; Kolb, T.

2017. The chemical engineering journal, 308, 1209–1224. doi:10.1016/j.cej.2016.09.101

Kutne, P.; Ebenhoch, M.; Meier, W.; Fleck, S.; Hotz, C.

2016. Optics InfoBase Conference Papers. Laser Applications to Chemical, Security and Environmental Analysis, LACSEA 2016; Kongresshaus Stadthalle HeidelbergHeidelberg; Germany; 25 July 2016 through 28 July 2016, Optica Publishing Group (OSA). doi:10.1364/LACSEA.2016.LM2E.2

Schneider, C.; Stoesser, P.; Rincon, S.; Kolb, T.

2016. The 41st International Technical Conference on Clean Coal & Fuel Systems, 05.-09.06.2016, Clearwater, Fl, USA

Jampolski, L.; Sänger, A.; Jakobs, T.; Kolb, T.; Willenbacher, N.

2016. Advanced Biofuels Symposium 2016, Vancouver, CDN, 06.-08.07.2016

Jampolski, L.; Tomasi-Morgano, M.; Jakobs, T.; Leibold, H.; Kolb, T.; Willenbacher, N.

2016. Advanced Biofuels Symposium 2016, 06.-08.07.2016, Vancouver, Canada

Eberhard, M.; Raffelt, K.; Sauer, J.; Kolb, T.

2016. ES2050 Workshop FT2 Biogene Energieträger, Frankfurt a. Main, 16.09.2016

Kutne, P.; Ebenhoch, M.; Meier, W.; Fleck, S.; Hotz, C.; Kolb, T.

2016. 2016 Imaging and Applied Optics Congress, Heidelberg, 25.-28.07.2016

Nau, P.; Kutne, P.; Eckel, G.; Meier, W.; Hotz, C.; Fleck, S.

2016. 2016 Imaging and Applied Optics Congress, July 25- 28, 2016 Heidelberg, Germany, Optica Publishing Group (OSA). doi:10.1364/LACSEA.2016.LM2E.3

Stoesser, P.; Schneider, C.; Kolb, T.

2016. 1st International Workshop on Oxy-Fuel Combustion Montabaur, 10.-11.02.2016

Müller, T.; Sänger, A.; Habisreuther, P.; Jakobs, T.; Kolb, T.; Zarzalis, N.

2016. Jahrestreffen der ProcessNet Fachgruppe „Hochtemperaturtechnik”, Erlangen-Nürnberg, 10.-11. März 2016

Kolb, T.; Aigner, M.; Kneer, R.; Müller, M.; Weber, R.; Djordjevic, N.

2016. Journal of the Energy Institute, 89 (4), 485–503. doi:10.1016/j.joei.2015.07.007

Müller, T.; Habisreuther, P.; Zarzalis, N.; Sänger, A.; Jakobs, T.; Kolb, T.

2016. ASME Turbo Expo. Turbomachinery Technical Conference and Exposition, Seoul, South Korea, June 14-16, 2016

Jakobs, T.; Sänger, A.; Kolb, T.

2016. Jahrestreffen der ProcessNet Fachgruppen „Energieverfahrenstechnik” und „Abfallbehandlung und Wertstoffrückgewinnung", Frankfurt am Main, 23.-24.02.2016

Jakobs, T.; Sänger, A.; Jampolski, L.; Willenbacher, N.; Kolb, T.

2016. Innovative Coal Value Chains. 8th International Freiberg Conference on IGCC & XtL Technologies. Köln, 12.-16.06.2016

Jampolski, L.; Jakobs, T.; Kolb, T.; Willenbacher, N.

2016. Rheologie als Schlüssel zu einem erfolgreichen Produktdesign. Gemeinsame Diskussionstagung der Deutschen Rheologischen Gesellschaft und der ProcessNet Fachgruppe „Rheologie" (DRG/ProcessNet – Rheologentagung), Berlin, 14.-15.03.2016

Sänger, A.; Jakobs, T.; Kolb, T.

2016. ILASS - Europe 2016, 27th Annual Conference on Liquid Atomization and Spray Systems, Brighton, UK, 04.-07.09.2016, Paper AA-18, 8 S., Fraunhofer IRB Verlag

Sänger, A.; Jakobs, T.; Kolb, T.

2016. 27th European Conference Liquid Atomization & Spray Systems (ILASS 2016), Brighton, United Kingdom, September 4–7, 2016

Fleck, S.; Hotz, C.; Kolb, T.

2016. DGMK-Tagung „Konversion von Biomassen und Kohlen”, Rotenburg a.d.Fulda, 09.-11.05.2016, 103–104, Deutsche Wissenschaftliche Gesellschaft für Erdöl, Erdgas und Kohle e.V. (DGMK)

Seebold, S.; Eberhard, M.; Wu, G.; Yazhenskikh, E.; Sergeev, D.; Kolb, T.; Müller, M.

2016. Innovative Coal Value Chains, 8th International Freiberg Conference on IGCC & XtL Technologies, Köln, 12.-16.06.2016

Müller-Hagedorn, M.; Covella, K.; Weigand, P.; Michelfelder, B.; Eberhard, M.; Kolb, T.

2016. 8th International Freiberg Conference on IGCC & XtL Technologies, Innovative Coal Value Chains, Köln, 12.-16.06.2016

Zimmerlin, B.; Eberhard, M.; Fridbjarnarson, G.; Galla, U.; Kolb, T.; Mai, R.; Michelfelder, B.; Niebel, A.; Weirich, F.; Willy, M.

2016. 9th International Seminar on Gasification, 19.-20. Oktober 2016, Malmö, Schweden

Mörs, F.; Bär, K.; Ortloff, F.; Graf, F.; Kolb, T.

2016. Chemie - Ingenieur - Technik, 88 (9), 1329. doi:10.1002/cite.201650390

Mörs, F.; Bär, K.; Ortloff, F.; Graf, F.; Kolb, T.

2016. 32. ProcessNet-Jahrestagung und 32. DECHEMA-Jahrestagung der Biotechnologen (2016), Aachen, Germany, September 12–15, 2016

Müller, T.; Habisreuther, P.; Zarzalis, N.; Sänger, A.; Jakobs, T.; Kolb, T.

2016. ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, South Korea, June 13–17, 2016, Volume 3: Coal, Biomass and Alternative Fuels, V003T03A003/1–11, The American Society of Mechanical Engineers (ASME). doi:10.1115/GT2016-56371

Müller, T.; Sänger, A.; Habisreuther, P.; Jakobs, T.; Trimis, D.; Kolb, T.; Zarzalis, N.

2016. International journal of multiphase flow, 87, 212–228. doi:10.1016/j.ijmultiphaseflow.2016.09.008

Stoesser, P.; Ruf, J.; Gupta, R.; Djordjevic, N.; Kolb, T.

2016. Energy & fuels, 30 (8), 6448–6457. doi:10.1021/acs.energyfuels.6b00935

Jampolski, L.; Sänger, A.; Jakobs, T.; Guthausen, G.; Kolb, T.; Willenbacher, N.

2016. Fuel, 185, 102–111. doi:10.1016/j.fuel.2016.07.102

Götz, M.; Lefebvre, J.; Mörs, F.; Reimert, R.; Graf, F.; Kolb, T.

2016. The chemical engineering journal, 286, 348–360. doi:10.1016/j.cej.2015.10.044

Ortloff, F.; Bohnau, J.; Graf, F.; Kolb, T.

2016. Applied catalysis / B, 182, 375–384. doi:10.1016/j.apcatb.2015.09.025

Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T.

2016. Renewable energy, 85, 1371–1390. doi:10.1016/j.renene.2015.07.066

Ortloff, F.; Bohnau, J.; Kramar, U.; Graf, F.; Kolb, T.

2016. Applied catalysis / B, 182, 550–561. doi:10.1016/j.apcatb.2015.09.026

Chaussonnet, G.; Braun, S.; Wieth, L.; Kolb, T.; Koch, R.; Bauer, H.-J.; Sänger, A.; Jakobs, T.; Djordjevic, N.

2015. 13th Triennial International Conference on Liquid Atomization and Spray Systems (ICLASS 2015), Tainan, TWN, August 23 - 27, 2015. Ed.: T. Lin, 1–8, National Cheng Kung University. doi:10.13140/RG.2.1.4320.7128

Kolb, T.

2015. Fall Task Meeting, IEA Task 33: Thermal Gasification of Biomass Berlin, 29.10.2015

Jampolski, L.; Sänger, A.; Jakobs, T.; Kolb, T.; Willenbacher, N.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Kolb, T.

2015. IEA Task 33: Thermal Gasification of Biomass Ponferrada, Spanien, 11.-13.05.2015

Sänger, A.; Jakobs, T.; Djordjevic, N.; Kolb, T.

2015. ICLASS 2015 / 13th International Conference on Liquid Atomization and Spray Systems : August 23-27, 2015, Tainan, Taiwan. Chairman: Ta-Hui Lin, A2–1

Sänger, A.; Jakobs, T.; Djordjevic, N.; Kolb, T.

2015. ICLASS 2015, 13th Triennial Intenational Conference on Liquid Atomization and Spray Systems, Tainan, Taiwan, 23.-27.08.2015

Sänger, A.; Jakobs, T.; Jampolski, L.; Willenbacher, N.; Kolb, T.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Kolb, T.; Eberhard, M.

2015. IEA Bioenergy: Task 33 Thermal Gasification of Biomass, Task Meeting, Berlin, 29.10.2015

Jampolski, L.; Sänger, A.; Djordjevic, N.; Kolb, T.; Willenbacher, N.

2015. Jahrestreffen der ProcessNet Fachgruppe "Rheologie", Ludwigshafen, 26.02.2015

Jampolski, L.; Djordjevic, N.; Kolb, T.

2015. 10th Annual European Rheology Conference (2015), Nantes, France, April 14–17, 2015

Jakobs, T.; Sänger, A.; Jampolski, G.; Chaussonnet, G.; Müller, T.; Willenbacher, N.; Zarzalis, N.; Bauer, H.-J.; Kolb, T.

2015. Bioliq Statusseminar - Querschnittsverbund Sustainable Bioeconomy, Karlsruhe, 01.12.2015

Kolb, T.; Eberhard, M.

2015. IEA Bioenergy - Task 33 - Thermal Gasification of Biomass - Task Meeting, Ponferrada, Spain, 11-13 May 2015

Graf, F.; Ortloff, F.; Kolb, T.

2015. Proceedings of the 26th World Gas Conference (WGC), Paris, 01.-05.06.2015

Lefebvre, J.; Götz, M.; Bajohr, S.; Reimert, R.; Kolb, T.

2015. Fuel Processing Technology, 132, 83–90. doi:10.1016/j.fuproc.2014.10.040

Kolb, T.; Djordjevic, N.

2015. 10th European Conference on Industrial Furnaces and Boilers (INFUB 2015), Vila Nova de Gaia, Portugal, April 7–10, 2015

Fleck, S.; Santo, U.; Hotz, C.; Boening, D.; Djordjevic, N.; Kolb, T.

2015. International Conference on Thermochemical (TC) Biomass Conversion Science, tcbiomass 2015, Chicago, USA, 02.-05.11.2015

Kolb, T.; Djordjevic, N.

2015. 10th European Conference on Industrial Furnaces and Boilers (INFUB 2015), Porto, P, April 7-10, 2015. Proceedings, CD-ROM

Fleck, S.; Hotz, C.; Stoesser, P.; Kolb, T.

2015. 27. Deutscher Flammentag (2015), Clausthal-Zellerfeld, Germany, September 16–17, 2015

Fleck, S.; Hotz, C.; Kolb, T.; Geigle, K. P.; Kutne, P.

2015. 27. Deutscher Flammentag (2015), Clausthal-Zellerfeld, Germany, September 16–17, 2015

Fleck, S.; Hotz, C.; Stoesser, P.; Kolb, T.

2015. Verbrennung und Feuerung : 27.Deutscher Flammentag, Clausthal-Zellerfeld, 16.-17.September 2015, 207–217, VDI Verlag

Fleck, S.; Hotz, C.; Kolb, T.; Geigle, K. P.; Kutne, P.

2015. Verbrennung und Feuerung : 27.Deutscher Flammentag, Clausthal-Zellerfeld, 16.-17.September 2015, 697–703, VDI Verlag

Jakobs, T.; Djordjevic, N.; Sänger, A.; Zarzalis, N.; Kolb, T.

2015. Atomization and sprays, 25 (12), 1081–1105. doi:10.1615/AtomizSpr.2015011558

Mueller, A.; Haustein, H. D.; Stoesser, P.; Kreitzberg, T.; Kneer, R.; Kolb, T.

2015. Energy & fuels, 29 (10), 6717–6723. doi:10.1021/acs.energyfuels.5b01123

Jakobs, T.

2015. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000048862

Hotz, C.; Fleck, S.; Djordjevic, N.; Kolb, T.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Fleck, S.; Geigle, K. P.; Hotz, C.; Djordjevic, N.; Kolb, T.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Graf, F.; Ortloff, F.; Götz, M.; Kolb, T.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Kutne, P.; Gounder, J. D.; Fleck, S.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Jampolski, L.; Sänger, A.; Djordjevic, N.; Kolb, T.; Willenbacher, N.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Anghilante, R.; Lefebvre, J.; Colomar, D.; Kolb, T.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Sänger, A.; Jakobs, T.; Djordjevic, N.; Jampolski, L.; Kolb, T.; Willenbacher, N.

2015. Energy, Science and Technology, Conference and Exhibition (EST 2015), Karlsruhe, Germany, May 20–22, 2015

Nolte, M.

2015. Karlsruher Institut für Technologie (KIT)

Jakobs, T.

2015. Karlsruher Institut für Technologie (KIT)

Dahmen, N.; Arnold, U.; Djordjevic, N.; Henrich, T.; Kolb, T.; Leibold, H.; Sauer, J.

2015. The journal of supercritical fluids, 96, 124–132. doi:10.1016/j.supflu.2014.09.031

Sänger, A.; Jakobs, T.; Djordjevic, N.; Kolb, T.

2014, September 8. 26th European Conference Liquid Atomization & Spray Systems (ILASS 2014), Bremen, Germany, September 8–10, 2014

Gunarathne, D. S.; Müller, A.; Fleck, S.; Kolb, T.; Chmielewski, J. K.; Yang, W.; Blasiak, W.

2014. Energy, 71, 496–506. doi:10.1016/j.energy.2014.04.100

Sänger, A.; Jakobs, T.; Djordjevic, N.; Kolb, T.

2014. 26th European Conference Liquid Atomization and Spray Systems : proceedings of the Conference; Bremen, Germany, 08.09.2014 - 10.09.2014. Ed: L. Achelis, Institute for Liquid Atomization and Spray Systems (ILASS)

Ortloff, F.; Graf, F.; Kolb, T.

2014. 1.Bioökonomie-Kongress Baden-Württemberg, Stuttgart, 29.-30.Oktober 2014

Gunarathne D. S.; Mueller A.; Fleck, S.; Kolb, T.; Chmielewski, J. K.; Yang, W.; Blasiak W.

2014. Energy & fuels, 28 (3), 1992–2002. doi:10.1021/ef402342e

Ortloff, F.; Götz, M.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T.

2014. Energie-, Wasser-Praxis, 66, 67–70

Hotz, C.; Fleck, S.; Santo, U.; Boening, D.; Stoesser, P.; Djordjevic, N.; Kolb, T.

2014. 4th International Symposium on Gasification and its Applications (iSGA 2014), Wien, A, September 2-4, 2014

Mätzing, H.; Gehrmann, H. J.; Kolb, T.; Seifert, H.

2014. 33rd International Conference on Thermal Treatment Technologies (It3), Baltimore, Md., October 13-15, 2014

Mueller, A.; Stoesser, P.; Kolb, T.

2014. 39th Internat.Technical Conf.on Clean Coal and Fuel Systems, Clearwater, Fla., June 1-5, 2014

Kolb, T.

2014. 4. Statuskonferenz der BMBF-Fördermaßnahme ’Technologien für Nachhaltigkeit und Klimaschutz - Chemische Prozesse und stoffliche Nutzung von CO2’, Königswinter, 8. April 2014

Kolb, T.; Zimmerlin, B.

2014. SGC International Seminar on Gasification, Malmö, S, October 15-16, 2014

Graf, F.; Bajohr, S.; Köppel, W.; Kolb, T.

2014. Jahrestreffen der ProcessNet-Fachgruppe ’Energieverfahrenstechnik’, Karlsruhe, 18.-19. Februar 2014

Kolb, T.; Weiss, M.; Zimmerlin, B.; Weigand, P.

2014. COORETEC-AG2 Treffen ’Vergasung kohlenstoffhaltiger Energieträger’, Darmstadt, 13. November 2014

Geigle, K. P.; Kutne, P.; Fleck, S.

2014. 6th International Freiberg Conference on IGCC & XtL Technologies (IFC 2014), Dresden, May 19-22, 2014

Kutne, P.; Geigle, K. P.; Fleck, S.

2014. 6th International Freiberg Conference on IGCC & XtL Technologies (IFC 2014), Dresden, May 19-22, 2014

Mueller, A.; Stoesser, P.; Kolb, T.

2014. Jahrestreffen der ProcessNet-Fachgruppe Abfallbehandlung und Wertstoffrückgewinnung, Gasreinigung und Hochtemperaturtechnik, Karlsruhe, 17.- 18. Februar 2014

Kolb, T.; Eberhard, M.; Seifert, H.; Zimmerlin, B.

2014. Berliner Abfallwirtschafts- und Energiekonferenz, Berlin, 27.-28. Januar 2014

Pudasainee, D.; Paur, H. R.; Fleck, S.; Seifert, H.

2014. 11th International Conference on Mercury as a Global Pollutant (ICMGP), Edinburgh, GB, July 28 - August 2, 2013

Pudasainee, D.; Paur, H. R.; Fleck, S.; Seifert, H.

2014. Fuel processing technology, 120, 54–60. doi:10.1016/j.fuproc.2013.12.010

Kolb, T.; Eberhard, M.

2013. IEA Bioenergy 2nd Semi-Annual Task Meeting ’Task 33: Thermal Gasification of Biomass’, Göteborg, S, November 19-21, 2013

Sänger, A.; Kolb, T.; Jakobs, T.; Djordjevic, N.; Zarzalis, N.

2013. 26.Deutscher Flammentag, Duisburg, 11.-12.September 2013

Kolb, T.; Eberhard, M.; Dahmen, N.; Leibold, H.; Neuberger, M.; Sauer, J.; Seifert, H.; Zimmerlin, B.

2013. DGMK International Conference ’New Technologies and Alternative Feedstocks in Petrochemistry and Refining’, Dresden, 9.-11. Oktober, 2013. Hrsg.: S. Ernst, Deutsche Wissenschaftliche Gesellschaft für Erdöl, Erdgas und Kohle e.V. (DGMK)

Sänger, A.; Kolb, T.; Jakobs, T.; Djordjevic, N.; Zarzalis, N.

2013. Verbrennung und Feuerung : 26.Deutscher Flammentag, Duisburg, 11.-12.September 2013, 321–331, VDI Verlag

Kolb, T.; Eberhard, M.; Dahmen, N.; Leibold, H.; Neuberger, M.; Sauer, J.; Seifert, H.; Zimmerlin, B.

2013. DGMK International Conference ’New Technologies and Alternative Feedstocks in Petrochemistry and Refining’, Dresden, October 9-11, 2013

Jakobs, T.; Kolb, T.

2013. Vortr.: Karlsruher Institut für Technologie (KIT), Karlsruhe, December 12, 2013

Fleck, S.; Stoesser, P.; Santo, U.; Flamme, M.; Kolb, T.

2013. Jahrestreffen Hochtemperaturtechnik und Technische Reaktionen, Oberhausen, 26.- 27.Februar 2013

Kolb, T.; Eberhard, M.; Zimmerlin, B.; Willy, B.

2013. Jahrestreffen der ProcessNet-Fachgruppe SuPER, 5.-6. November 2013

Kolb, T.

2013. 1st European Conference on Technology to Business in Energy from Chemical Fuels, Frankfurt, September 23-24, 2013

Bajohr, S.; Götz, M.; Graf, F.; Kolb, T.

2013. Gasfachliche Aussprachetagung (GAT 2013), Nürnberg, 1.-2. Oktober 2013

Ortloff, F.; Graf, F.; Kolb, T.

2013. Gas for Energy, (3), 58–65

Ortloff, F.; Bajohr, S.; Graf, F.; Kolb, T.

2013. GWF / Gas, Erdgas, 154 (10), 762–769

Götz, M.; Ortloff, F.; Reimert, R.; Basha, O.; Morsi, B. I.; Kolb, T.

2013. Energy & fuels, 27 (8), 4705–4715. doi:10.1021/ef400334p

Mancini, M.; Weber, R.; Weigand, P.; Leuckel, W.; Kolb, T.

2013. 26.Deutscher Flammentag, Duisburg, 11.-12.September 2013

Mancini, M.; Weber, R.; Weigand, P.; Leuckel, W.; Kolb, T.

2013. Verbrennung und Feuerung : 26.Deutscher Flammentag, Duisburg, 11.-12.September 2013, 625–634, VDI Verlag

Sänger, A.; Mancini, M.; Weber, R.; Weigand, P.; Kolb, T.

2013. 38th International Technical Conference on Clean Coal and Fuel Systems, Clearwater, Fla., June 2-6, 2013

Kolb, T.

2013. Sustainable bioeconomy : gemeinsam mit Workshop BioBoost, 28. und 29. November 2012; Vorträge, Karlsruher Institut für Technologie (KIT), Campus North, CD-ROM, Karlsruher Institut für Technologie (KIT)

Götz, M.; Bajohr, S.; Graf, F.; Reimert, R.; Kolb, T.

2013. Chemie - Ingenieur - Technik, 85 (7), 1146–1151. doi:10.1002/cite.201200212

Götz, M.; Bajohr, S.; Kolb, T.

2013. 3rd International Conference on Energy Process Engineering (ICEPE 2013), Frankfurt, June 3-6, 2013

Kolb, T.

2013. Wind-to-Gas : 4.Energiekolloquium der Chemiegesellschaften, 707.DECHEMA-Kolloquiumm, Frankfurt, 7.März 2013

Arias, F.; Kolb, T.; Seifert, H.; Gehrmann, H.-J.

2013. Chancen der Energiewende : wissenschaftliche Beiträge des KIT zur 1. Jahrestagung des KIT-Zentrums Energie, 19.06.2012. Hrsg.: W. Breh, 71–76, KIT Scientific Publishing

Fleck, S.; Stoesser, P.; Santo, U.; Flamme, M.; Kolb, T.

2013. Jahrestreffen Hochtemperaturtechnik und Technische Reaktionen, Oberhausen, 26.- 27.Februar 2013

Ortloff, F.; Graf, F.; Kolb, T.

2012. Energie-, Wasser-Praxis, 62 (12), 96–99

Dahmen, N.; Dinjus, E.; Kolb, T.; Arnold, U.; Leibold, H.; Stahl, R.

2012. Environmental progress & sustainable energy, 31 (2), 176–181. doi:10.1002/ep.10624

Mätzing, H.; Gehrmann, H.-J.; Kolb, T.; Seifert, H.

2012. Environmental Engineering Science, 29 (10), 907–914. doi:10.1089/ees.2011.0556

Jakobs, T.; Djordjevic, N.; Fleck, S.; Zarzalis, N.; Kolb, T.

2012. 12th International Conference on Liquid Atomization and Spray Systems (ICLASS 2012), Heidelberg, September 2-6, 2012

Jakobs, T.; Djordjevic, N.; Fleck, S.; Zarzalis, N.; Kolb, T.

2012. 12th International Conference on Liquid Atomization and Spray Systems (ICLASS 2012), Heidelberg, September 2-6, 2012. Ed.: E. Gutheil, CD-ROM, ILASS Europe

Kolb, T.

2012. Kolloquium Sustainable BioEconomy, Karlsruhe, 28.-29. November 2012

Graf, F.; Kolb, T.

2012. World Gas Conf.2012, Kuala Lumpur, MAL, June 4-8, 2012

Kolb, T.; Aigner, M.; Kneer, R.; Müller, M.; Weber, R.

2012. 5th International Freiberg Conference on IGCC & XtL Technologies (IFC 2012), Leipzig, May 21-24, 2012

Kolb, T.

2012. 4th European Economic Congress (EEC), Katowice, PL, May 14-16, 2012

Kolb, T.; Dahmen, N.

2012. 18.Fachtagung Energetische Nutzung nachwachsender Rohstoffe, Freiberg, 13.-14.September 2012

Kolb, T.; Weigand, P.

2012. 77.Sitzung des DGMK Arbeitskreises Kohleveredlung, Frankfurt, 9.November 2012

Götz, M.; Ortloff, F.; Reimert, R.; Kolb, T.

2012. ProcessNet-Jahrestagung und 30. DECHEMA-Jahrestagung der Biotechnologen 2012, Karlsruhe, 10.-13.September 2012

Graf, F.; Kolb, T.

2012. World Gas Conf. 2012, Kuala Lumpur, MAL, June 4-8, 2012, International Gas Union

Bajohr, S.; Götz, M.; Graf, F.; Kolb, T.

2012. GWF / Gas, Erdgas, 153 (5), 328–335

Mätzing, H.; Gehrmann, H. J.; Kolb, T.; Seifert, H.

2012. ProcessNet-Jahrestagung und 30. DECHEMA-Jahrestagung der Biotechnologen 2012, Karlsruhe, 10.-13.September 2012 Chemie Ingenieur Technik, 84(2012) (Abstract)

Pudasainee, D.; Paur, H. R.; Bologa, A.; Woletz, K.; Fleck, S.; Kolb, T.; Seifert, H.

2012. ProcessNet-Jahrestagung und 30. DECHEMA-Jahrestagung der Biotechnologen 2012, Karlsruhe, 10.-13.September 2012 Chemie Ingenieur Technik, 84(2012) (Abstract)

Jakobs, T.; Djordjevic, N.; Fleck, S.; Mancini, M.; Weber, R.; Kolb, T.

2012. Applied Energy, 93, 449–456. doi:10.1016/j.apenergy.2011.12.026

Fleck, S.; Santo, U.; Navatta, R.; Stoesser, P.; Flamme, M.; Kolb. T.

2011. 19th European Biomass Conference and Exhibition. From Research to Industry and Markets (2011), Berlin, Germany, June 6–10, 2011

Gehrmann, H.-J.; Kolb, T.; Seifert, H.; Mark, F. E.; Frankenhaeuser, M.; Schanssema, A.; Wittstock, K.; Kolb, J. J.

2010. Environmental engineering science, 27 (7), 557–567. doi:10.1089/ees.2009.0373

Fleck, S.; Fertl, P.; Kolb, T.

2010. Third International Symposium on Energy from Biomass and Waste ; Cini Foundation, Venice, Italy, 8 - 11 November 2010, Cisa Publ

Fertl, P. T.; Eberhard, M.; Kolb, T.; Bajohr, S.; Reimert, R.

2009. Chemie - Ingenieur - Technik, 81 (8), 1141. doi:10.1002/cite.200950433

Gehrmann, H.-J.; Kolb, T.; Seifert, H.; Mark, F. E.; Frankenhaeuser, M.; Schanssema, A.; Wittstock, K.; Kolb, J. J.

2009. Joint Conference: International Thermal Treatment Technologies (IT3) and Hazardous Waste Combustors (HWC), Cincinnati, OH, May 18-21, 2009, 1–16, New York

Kolb, T.; Gehrmann, H.-J.; Stein-Brzozowska, M.; Seifert, H.

2008. 8th European Conference on Industrial Furnaces and Boilers (INFUB), Vilamoura, Portugal, 25.-28.03.2008

Kolb, T.; Bleckwehl, S.; Gehrmann, H.-J.; Seifert, H.

2008. Journal of the Energy Institute, 81 (1), 1–6. doi:10.1179/174602208X269526

Schaub, G.; Kolb, T.; Steiger, W.

2007. Chemie - Ingenieur - Technik, 79 (9), 1325–1326. doi:10.1002/cite.200750169

Kolb, T.; Gehrmann, H.-J.; Seifert, H.

2006. Ressourcenmanagement: Das zentrale Element für unternehmerisches und kommunales Handeln. Abfalltage Baden-Württemberg, Stuttgart, 26.-27.09.2006

Ebert, V.; Schlosser, E.; Oser, B. L.; Kolb, T.; Wolfrum, J. M.

2005. Chemie - Ingenieur - Technik, 77 (8), 1109. doi:10.1002/cite.200590341

Kolb, T.; Dinjus, E.; Henrich, E.; Krebs, L.

2004. Fachtagung "Pyrolyse- und Vergasungsverfahren in der Energietechnik - Bio-Fuel-Konzepte", Freiberg, 4.-5.3.2004

Kolb, T.; Leibold, H.; Bleckwehl, S.; Walter, R.

2003. Primärseitige Stickoxidminderung als Beispiel für die Optimierung des Verbrennungsvorgangs in Abfallverbrennungsanlagen. Abschlussbericht des HGF- Strategiefonds-Projektes. Hrsg.: H. Seifert, 145–171, Forschungszentrum Karlsruhe (FZKA)

Kolb, T.; Seifert, H.; Kranert, M.; Thomanetz, E.

2003. Winnacker-Küchler: Chemische Technik: Prozesse und Produkte. Band 2: Neue Technologien. Hrsg.: R. Dittmeyer, Wiley-VCH Verlag

Kolb, T.

1996. VDI Seminar 43-54-14: Betrieb von Rückstandsverbrennungsanlagen, Düsseldorf/Dormagen, 6./7.02.1996

Kolb, T.; Poplow, F.; Straßburger, R.; Christill, M.

1995

Kolb, T.; Joschek, H.-I.; Dorn, I. H.

1995. VGB-Kraftwerkstechnik, 75 (4), 370–379

Kolb, T.

1994. Seminar U14: "Thermische Abfallbehandlung", Kernforschungszentrum Karlsruhe, 05.-07.10.1994

Kolb, T.; Steinebrunner, K.; Dorn, I. H.; Seifert, H.

1994. 25th International Symposium on Combustion, University of California, Irvine, 31.07.-05.08.1994

Kolb, T.

1994. Automobilkreis-Fachtagung "Rohstoffliche und Thermische Verwertung", Bad Nauheim, April 1994

Kolb, T.; Baumgartner, H. P.; Christill, M.; Dorn, I. H.; Seifert, H.

1994. GVC Symposium Abfallwirtschaft, Würzburg 1994

Kolb, T.; Dorn, I. H.; Christill, M.; Hess, K.

1994. Chemie - Ingenieur - Technik, 66 (9), 1167–1168. doi:10.1002/cite.330660907

Kolb, T.; Dorn, I. H.; Christill, M.; Hess, K.

1994

Straßburger, R.; Kolb, T.; Mantel, R.; Seifert, H.; Dorn, I. H.

1993. Chemie - Ingenieur - Technik, 65 (9), 1100. doi:10.1002/cite.330650983

Kolb, T.; Seifert, H.

1993. Verbrennungsanlagen für Sonderabfall, Mannheim, 7. - 8.September 1993, VDI-Bildungswerk

Kolb, T.; Hillemanns, R.; Baumgartner, H.; Seifert, H.; Groß, K.; Dorn, I. H.

1992. GVC-Jahrestreffen Verfahrensingenieure, Wien, Österreich, 1992

Kolb, T.; Hillemanns, R.; Baumgartner, H.; Seifert, H.; Groß, K.; Dorn, I. H.

1992. Chemie - Ingenieur - Technik, 64 (9), 791. doi:10.1002/cite.330640936

Kolb, T.; Sybon, G.

1992. BWK, 44 (11), 481–484

Kolb, T.

1990. VGB-Kraftwerkstechnik, 70 (8)

Kolb, T.; Ritz, J.

1989. Saarbergwerke AG

Kolb, T.; Leuckel, W.; Jansohn, P.

1989. VDI-Berichte, (765), 231–244

Kolb, T.; Leuckel, W.; Jansohn, P.

1989. 14. Deutscher Flammentag (1989), Stuttgart, Germany, October 5–6, 2005

Kolb, T.; Jansohn, P.; Leuckel, W.

1989. Joint Meeting of the German and Italian Sections of the Combustion Institute, Ravello, 1989

Kolb, T.; Leuckel, W.; Jansohn, P.

1989. 9th Members Conference, Clean Combustion in Flames, IFRG, 1989

Kolb, T.; Leuckel, W.; Jansohn, P.

1989. 1st Topic Oriented Technical Meeting (ToTeM), Amsterdam, NL, 17.-19.10.1989

Kolb, T.; Ritz, J.; Jansohn, P.; Leuckel, W.

1989. Joint Meeting of the British and French Section of the Combustion Institute, Rouen, France, 1989

Kolb, T.; Leuckel, W.

1988. 4. TECFLAM-Seminar, Stuttgart, November 1988

Kolb, T.; Jansohn, P.; Leuckel, W.

1988. 22nd International Symposium on Combustion, Seattle, WA, USA, 14.-19.08.1988

Kolb, T.; Leuckel, W.

1988. Internes TECFLAM-Seminar, Heidelberg, Juni 1988

Kolb, T.; Leuckel, W.; Jansohn, P.

1988. 1st European Conference on Industrial Furnaces and Boilers (INFUB), Lisbon, Portugal, 1988

Kolb, T.; Farmayan, W. F.; Walsh, P. M.; Beér, J. M.

1988. Combustion science and technology, 58 (1-3), 77–95. doi:10.1080/00102208808923957