BRENDA:

Description:

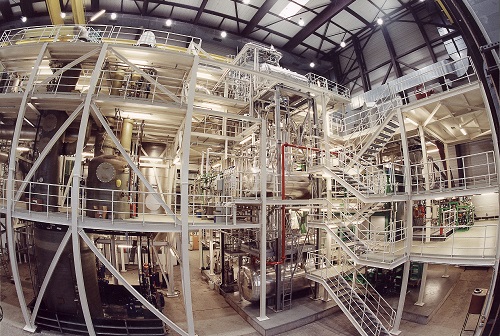

BRENDA (Brennkammer mit Dampfkessel) is a power plant combustion chamber at pilot scale for gaseous, liquid and dust-type fuels with a cylindrical, vertically arranged combustion chamber and a thermal output of 2,5 MW. The combustion chamber can be fed with gaseous, liquid and dust-type fuels through a swirl burner, an annular gap and centrally arranged lances. The swirl burner was designed by the company SAACKE and has a thermal output of 1 MW.

In order to reduce the CO2-Emissions caused by burning fossil fuels, biomass for generating power gain in importance. With BRENDA the combustion and emission behaviour of conventional and alternative fuels used in power plants can be analysed.

Beside the pilot combustion chamber, numerical models for assessing and supporting the combustion behaviour are developed. In the course of the energy transistion, the focus lies upon

the improvement of the load flexibility of consisting power plants. In combination with the fuel flexibility both challenges can mastered by using biogenic fuels during load changes.

| Performance data BRENDA | |

|---|---|

| Total thermal output | 2.5 MW |

| Height of combustion chamber | 17 m |

| Diameter of combustion chamber | 1.8 m |

| Dustfiring | 1 MW |

| Fuel throughput (depending on the calorific value) | 50 up to 200 kg/h |

| Thermal output of the main burner | 1.5 MW |

| Type of the burner: | |

| Horizontal arranged swirl burner with a central feeding and annular gap feeding system. | |

| Basic flow through the main combustion chamber (rotary kiln) | |

| Flue gas treatment according to 17. BImSchV | |